Benefits of Anti-Kickback and BG Test Router Bits

Anti-Kickback.....or ‘BG’ Test?

The term ‘Anti-Kickback’ has been an industry topic for quite some time and relates to cutting tools such as router bits, saw blades, etc. There are several brands of ‘Anti-Kickback’ router bits presently on the market and all of them, it seems, would offer some degree of safety to the end-user because they limit the ‘chip-thickness’ of the material being cut. In other words, the cutting tool will take less of a ‘bite’, thereby decreasing the likelihood of a kickback. While this is true, however, it should be pointed out that there are significant details to be considered when designing, manufacturing and using industrial cutting tools.

1. What is ‘BG’? ‘BG’ is an acronym for ‘Holz Berufsgenossenschaft’, the German Woodworking Trade Association. For the sake of worker safety, this esteemed group has established basic rules for the design, manufacturing and use of cutting tools for the wood and plastic industries.

These basic rules concern testing the working safety of woodworking machine tools. They establish test procedures and indicate all essential regulations and rules of technology, which need to be taken into account during testing. Precise geometric design, as well as the use of high quality materials and replacement parts complying with DIN standards, will ensure a safe tool with a high degree of precision in the production and the balance of the tools. The purpose of the test is to ascertain whether it is ensured that users or third parties, who are handling the tools properly are, in fact, protected as far as possible from risk to life or health.

Tools for use in wood and plastic working are classified into two groups: manual feed operations and mechanical feed operations.

Manual Feed Operations

‘Manual feed’ describes the holding and/or guiding by hand of the workpiece or of a machine element incorporating a tool. Manual feed includes the use of a hand-operated carriage, on which the workpiece is placed manually or clamped and the use of a demountable power feed unit.

Tools for manual operation marked ‘BG-TEST’ are designed according to the following rules:

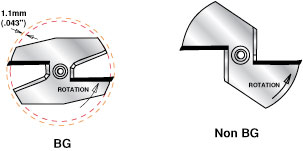

a) Thickness of chip limit with a maximum cutting edge projection of 1.1mm (.043"), over the total length of the cutting profile;

b) Restricted maximum chip clearance width, including the regrinding range as a function of the cutting flight circle;

c) Kickback ratio must not exceed 0.25 Vr/Vs < 0.25 (where Vs = cutting velocity and Vr = kickback velocity).

Special purpose tools which, for reasons of speed and economy, cannot be inspected by the German Woodworking Trade Association may be used manually, if they conform with the above requirements.

Mechanical Feed Operation

‘Mechanical feed’ means a feed mechanism for the workpiece or tool, which is integrated with the machine and where the workpiece or machine element with incorporated tool are held and controlled mechanically during the machining operation.

All the tools may be used for mechanical feed operation. The rules that characterize manual feed operation tools do not apply to them, except for the manufacturer’s label and maximum permitted speed. The basic rules applying to manual feed operations do not apply to router bits with diameters smaller

than 16mm.

2. ‘BG’ Form vs ‘BG’ Test - ‘BG’ Form is a term indicating cutting tools which have the same general circular shape of ‘BG’ Test tools, but which do not comply with the strict regulations governing ‘BG’ Test as outlined above. (1.1mm cutting edge projection, restricted maximum chip clearance width etc.) There is a significant difference between the two.

Important Note: Unless specified otherwise, all router bits over 16mm (5/8") diameter in this catalog are ‘BG-TEST’. This does not apply to CNC, Insert and tools with larger than 1/2" shank diameter.