Understanding the Jointer

Setting Jointer Knives

Woodworking tools work great when they are set up correctly, but when they are not they can become frustrating, damaging and expensive. The jointer is a complex tool whose knives must be set up accurately. The goal of this article is to break down its complexities and illustrate that it can be simple to accurately set jointer knives.

The purpose of a jointer is to smooth and square edges and faces of boards. Keeping a flat edge is especially important when you are required to glue two boards together, attached by their edges. The edges must be completely flat and straight in order to get a strong glued edge as well as an aesthetically clean surface without any gaps.

A problem with jointers is that if they are not set up properly, you can get large pieces chipping off or even end up with an edge that is arched when it should be completely flat. If you end up with boards which are chipped or arched, they become impossible to use.

One problem could be caused by the cutter head knives being set lower than the out feed table. If this is the case, the board edge will become arced. To properly set up the cutter head for a clean, straight edge the knives from the cutter head must be slightly higher than the out feed table.

The way to adjust this height depends on the machine, but the way to raise and lower the knives is generally done with the help of springs between the cutter head and the knives. Cutter heads usually have springs which allow the knives to be moved up and down for adjustment as they are being set.

The way to figure out the exact height the blade of the joiner needs to be, is by laying out a straight steel edged ruler flat on the out feed table. Rotating the cutter head by hand, the knives should slightly grab the ruler, and it should lift it up ahead and pull it forward between 1/8-1/4 inch. Anything higher or lower will create problems. Being too low will create an arc and being too high will result in taking chunks out of the back.

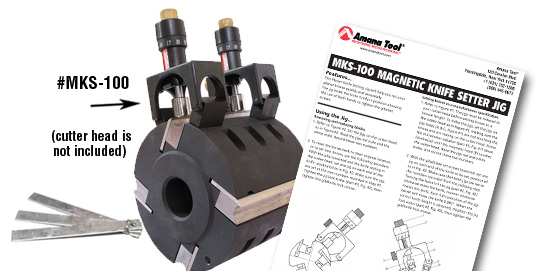

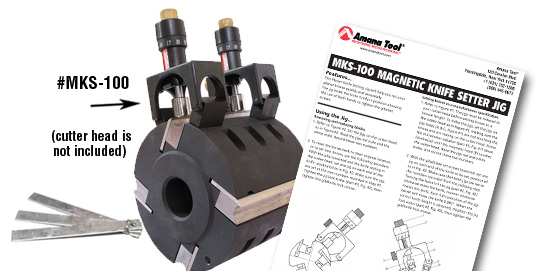

The above is a general account of how one sets joiner blades. All jointers are different. Therefore, settling the blades in place requires different methods. Some have no manufacturer's way to set the blades. If your jointer does not have a way to set blades, there is a great tool to assist you – the magnetic knife setter.

Shop for #MKS-100 Magnetic Knife Setter for Planers & Jointers now!