Amana Tool® Compression Spiral Router Bits

When working with plywood on a CNC router, the plywood is often prone to fuzziness on the edges and chipped veneers, resulting in hand sanding to get the edges to look nice.

Here are a few of my tips to cut down on the cleanup times.

1) Ensure the bits are sharp. As your router bits churn through thousands of feet you shouldn't be surprised how quickly they dull.

2) Consider whether you're performing a climb or conventional cut. Climb cuts often perform better in plywood.

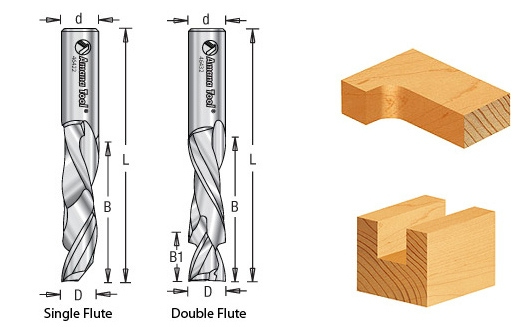

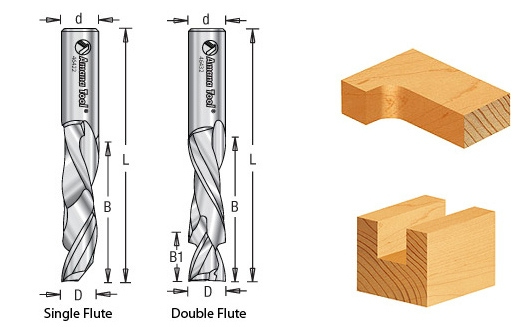

3) Choosing the right but makes the biggest impact on the quality of the cut. I prefer the compression spirals from Amana Tool, in particular the 1/4″ and 3/8″ bits from Toolstoday.com. The upcut router bits are excellent for clearing chips while preserving the veneer on the bottom of your material while the downcut spirals are great for a clean top edge. If you want a clean edge on both the top and bottom you will need a compression spiral.

The bottom of the compression spiral router bit (B1) is shaped to pull chips up, while the the rest of the bit cuts down resulting in a bit that doesn’t chip the veneer on either face of your laminated sheet goods and plywood.

I’ve been using these Amana bits for a few months now and I love them. They have become my goto bit. While they may be a bit more expensive than your standard single direction bit, the time saved in sanding and cleaning up ragged edges more than makes up for it.

Originally posted on April 4th, 2014 by Greg from Tinker and Futz here